SoundCell is a company with a mission to improve infectious disease outcomes for patients by speeding up diagnostics. To accomplish this mission, CEO Irek Roslon applied for a NanoLabNL voucher. With this voucher, SoundCell can use the facilities in the Cleanroom of the Kavli and Else Kooi NanoLab in Delft. Last month, Marc Zuiddam handed the NanoLabNL voucher to Irek.

Designing optical lithography masks

Irek Roslon: “With our research, we are working towards a wafer-scale production flow for silicon chips with arrays of cavities with a density of 5,000-10,000 cavities per mm2. We are now working towards a pilot production to facilitate our first in-hospital tests. Thanks to the NanoLabNL voucher, we can design optical lithography masks in the Cleanroom to produce these chips using methods compatible with the semiconductor industry.”

About SoundCell

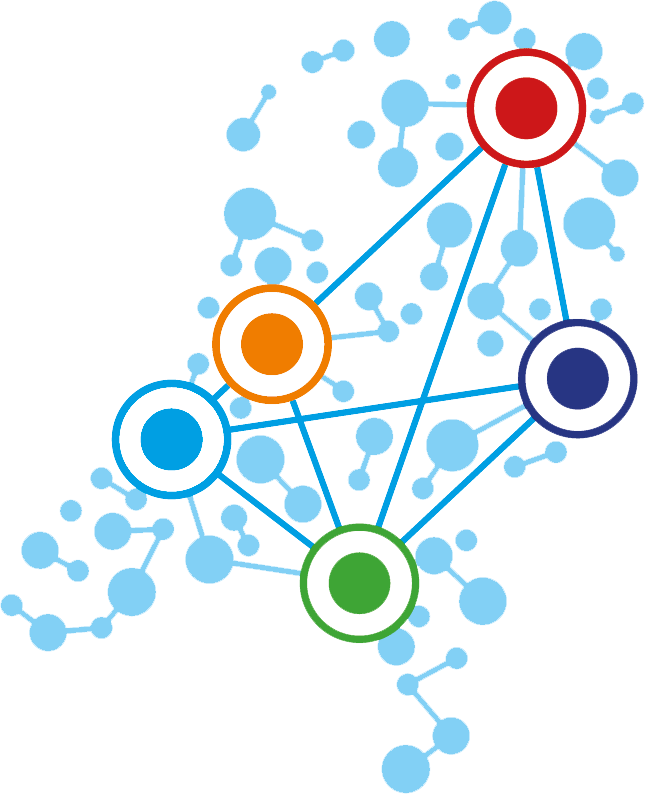

SoundCell is a TU Delft spin-off developing a graphene sensor technique that reduces the AST time from a few days to 1 hour. Rapid Antimicrobial Susceptibility Testing (AST) plays a crucial role in determining the type and concentration of antibiotics required to inhibit the growth of a pathogen. SoundCell’s graphene-based biosensor technology uses nanomechanical vibrations of ultrathin micronsized graphene drums to detect the motion of a single bacterium. Nanomotion of alive and dead bacteria is different when adhered to the graphene sensors and SoundCell’s technology can correlate such changes to antibiotic susceptibility. Starting this year, first devices will be validated in clinical setting in collaboration with Reinier Haga Medical Centre and Erasmus MC.