We are happy to announce the commissioning and upcoming installation of a large number of new tools. It is thanks to the national growth fund QuantumDeltaNL that we have been able to fund this investment program in the replacement of old equipment and introduction of new capabilities. The program is executed under the Dutch consortium of nano-fabrication cleanrooms NanoLabNL. Please see the text below for more details about these systems and whom to contact if you want to know more.

A new PolyTeknik cluster for sputter deposition has been installed. The system has one chamber for metals (5 targets) and one for dielectrics (5 targets). It is equipped with a load lock for a 24-fold 100mm wafer cassette or a 10-fild double pitch cassette for Mo carriers. Current set of targets is: W, Ti, Mo, Au, ITO, Si3N4, SiO2, TiO2, Al2O3, HfO2. Upon request by users other targets can be purchased.

For more information, please contact Tom vd Kraats or Patrick Bax (after 01-02-2025)

PolyTeknik Sputter tool

The old Helium liquefier in Cascade has been replaced by a modular system by Quantum Design. The system is operational as part of the He recovery system.

For more information please contact Herman Leijssen.

Quantum Design He liquefier

A new Temescal FC20413 evaporator is installed next to the current FC2000. It comprises a new option for dual axis substrate rotation (100mm only, see image on the right). For single axis rotation 3” and 2” wafers as well as piece parts can be loaded too. This system also has 8 evaporation pockets, and we are open to introducing new materials (Pd and Nb pellets already in place) and will create a back-up option for most frequently used materials like Ti, Pt and Au.

For more information please contact Erik Jan Geluk.

A new capability of NanoLab is 3D structuring by 2-photon lithography. For this purpose, we purchased a NanoScribe Quantum X-shape. It is foreseen to place this machine in the new cleanroom. For the time being it is in Flux 4.097, a lab of Jane-Mieke Meijer. The machine still needs to be installed.

Since the beginning of this year we have a LatticeGear LattiiceAx420 tool for micro-line indent and cleaving. It is located opposite the entrance part of the cleanroom next to the cleaving work bench.

For more information please contact Patrick Bax.

A new Trymax NEO 200A tool has been installed next to the existing Trymax microwave stripper. The new machine has RF bias option which enables reactive etching of polymers. It will replace the old Oxford Instruments polymer RIE in due time. Tool commissioning and acceptance is planned in Jan next year.

For more information please contact Tjibbe de Vries.

A Thermo Fisher Helios 5UX FIB/SEM (also known as Dual Beam) has been installed in Spectrum 0.55. The new system offers more sensitive EDS, automated slice and view, semi-automated TEM lamellae fabrication, various EM detection modes including STEM and ion assisted deposition form various gas sources.

For more information please contact Beatriz Barcones.

FIB-SEM Dual Beam – replacement

Very recently a KLA Candela 8420 machine for particle inspection was installed. It is capable of quantitative particle analysis as well as qualitative analysis by discriminating between particles, scratches, growth defects, spin coating artifacts etc. The tool is still in the commissioning phase and introduction to users is expected in Jan 2025.

For more information please contact Jeroen Bolk.

KLA defect inspection tool

Also very recently a new Thermo Fisher Nexsa G2 XPS analysis tool has been installed and is in the commissioning phase by the supplier. The machine replaces the old k-alpha machine and offers additional functionality with bipolar analyzer electronics to allow both negative (electrons) and positive (ions) energy selection.

The tool is still in the commissioning phase and introduction to users is expected in Jan 2025.

For more information please contact Barathi Krishnamoorthy.

A Filmetrics R50 4PP measurement tool is available in the cleanroom since March this year. It can be used to map the 4-point probe resistance of (conductive) thin films, and yield information on resistivity and thickness.

For more information please contact Erik Jan Geluk.

Four-point probe

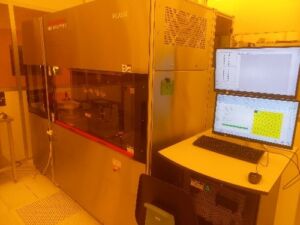

The MLA150 has not yet passed all acceptance criteria, but it is already available for use. Users can request access through NIS to start developing their own processes. Pending items include a significant software update to enhance batch-level automated processing, and the completion of the final tool owner training for maintenance and operation. Additionally, a special chuck for exposing small piece parts has been ordered. An investigation is currently ongoing on process stability issues observed with the high-resolution resist.

MLA150 direct write UV lithography

Latest articles

Join us at the NanoLabNL Userday 2025

Annelies Tielenburg2025-10-13T16:11:59+02:00October 9th, 2025|News|

Succesfull NanoLabNL Operator Day

Annelies Tielenburg2025-05-15T16:43:23+02:00May 15th, 2025|News|

IUVSTA workshop on ultra-clean vacuum

Jeanine Valster2025-01-10T14:40:47+01:00January 10th, 2025|News|